Process Improvement

We have the expertise to implement a customized process improvement plan based on Six Sigma principles. It is an important part of ensuring that your business runs smoothly and efficiently.

What is Process Improvement? .

The Strategy: Six Sigma

Six Sigma is a widely used business strategy that gets its roots in quality management. It seeks to identify and eliminate defects in any process, ranging from production and manufacturing to service delivery and customer experience. Developed by Motorola in the 1980s, Six Sigma has gone on to become renowned for helping companies increase efficiency and financial gains via improved effectiveness. Companies that have adopted this model often experience better processes, reduced costs, higher customer satisfaction rates, increased product consistency, and overall lowered project risk. Such loyalty to Six Sigma comes as no surprise given its well-known successes with General Electric and Honeywell.

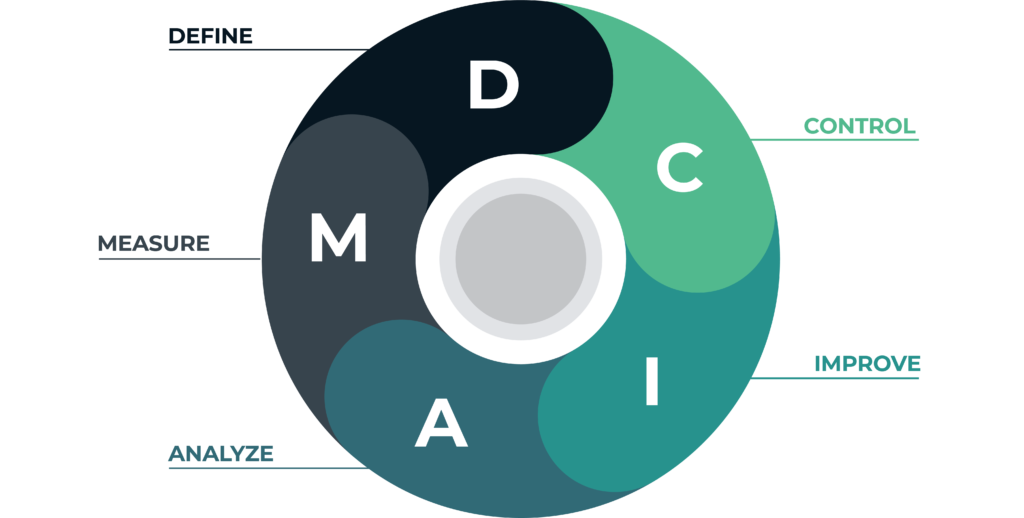

One of the best ways to improve processes and operations is to use the DMAIC method. This acronym stands for Define, Measure, Analyze, Improve, and Control. It's a problem-solving methodology used in many fields including engineering, management science, finance, medicine, and operations management. With DMAIC, you can break down each phase of a process in order to focus on improving it individually. This will help you pinpoint any areas where improvement could be made that may not have been visible before. By the end of this process, you'll have greater insight into how your process works and can ensure stability and quality by establishing control methods for consistency in the future.

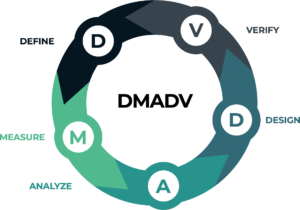

DMADV is an acronym for the Six Sigma process of Define, Measure, Analyze, Design, and Verify. It's a system for product and process improvement that uses data-driven decision-making to improve existing designs and processes or create new ones. DMADV is instrumental in project management through identifying critical points, analysis of areas to be improved, and positive testing to ensure the desired results are achieved. Using DMADV with Six Sigma projects, companies can reduce costs and boost profits by increasing efficiency and streamlining resources.

Cause and effect analysis is used to understand how certain actions and decisions can cause outcomes or results. It is important for businesses, organizations, governments, and individuals to consider the potential implications of their decisions in order to make sound planning choices. Through a cause and effect analysis, it is possible to establish relationships between various events and the outcomes or processes they create, allowing stakeholders informed decision-making going forward. Using this type of analysis prioritizes decisions by helping distinguish short-term costs or delays from long-term gain – both within financial considerations and also in reference to public satisfaction. Therefore, it can be extremely useful when making large-scale changes or commitments within any given situation.

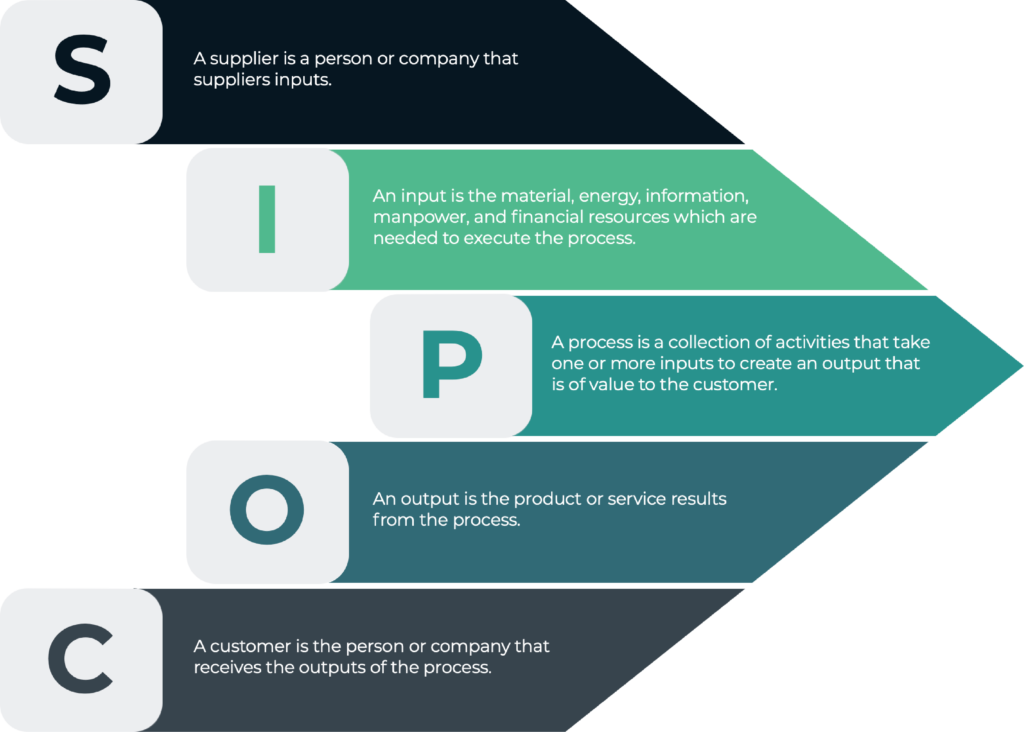

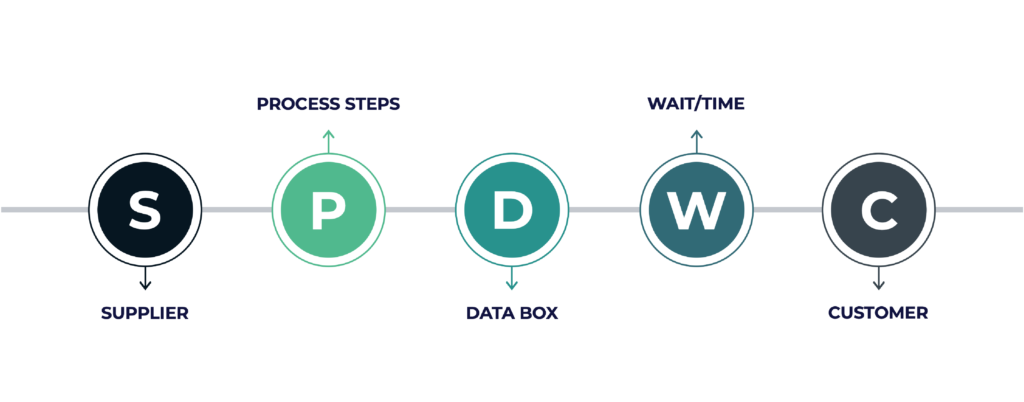

A SIPOC analysis (suppliers, inputs, processes, outputs, and customers) is a useful tool for businesses to evaluate the chain of activities related to producing a product or service. By clearly understanding which suppliers provide inputs, what processes are used to achieve an output, and who the customers are that drive demand for the final product or service, businesses can better understand their external environment. Utilizing this knowledge can help maximize resources and create more efficient internal operations while also anticipating changes in customer needs that may require adaptation in production. Businesses should take advantage of the comprehensive view that SIPOC analysis provides in order to remain competitive in their industries.

Value Stream Mapping (VSM) is a powerful strategy used to visualize and analyze the flow of materials and information used to create a product. It allows processes, resources, and bottlenecks in the production process to be identified quickly and easily, enabling organizations to optimize the existing production process or develop a new one. By analyzing both physical movements of goods and data flows along the value stream, VSM can help managers get valuable insight into their production process, ensuring that products are being created as efficiently as possible. This in turn can lead to increased customer satisfaction, improved product quality, and decreased operational costs. VSM is increasingly becoming an important part of operational excellence for companies looking to stay competitive in today's marketplace.

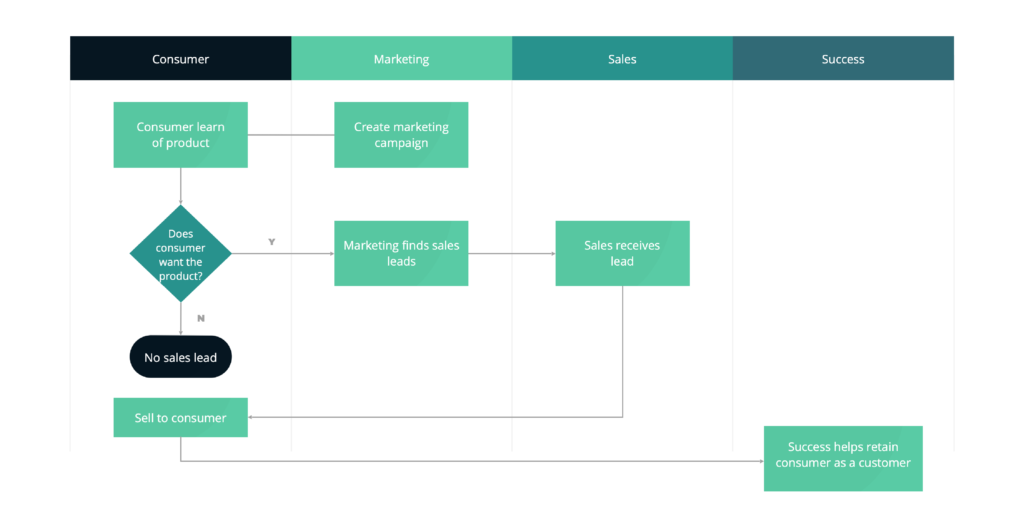

Process mapping is an important business analysis tool and can be used in almost every industry. This technique helps to identify tasks, uncover how they are connected, and describe how they flow, which makes it a great way to increase efficiency by organizing and streamlining procedures. Process mapping also can help identify areas to reduce spending, eliminate manual processes with automation, as well as create clear policies and training techniques. Companies often find that process mapping adds clarity and direction for employees, providing an overview of their roles within the organization at a glance. In short, effective process mapping is essential for any business looking to cut costs and optimize efficiency.

Improve Your Processes with Konnen Consulting

Change Management

This is essential for any business that wants to remain competitive in an ever-changing environment. Konnen Consulting can help you create an effective change management strategy.

LMS Evaluation & Support

We will help implement an LMS to train employees, track their progress, measure the effectiveness of your online training courses, and evaluate the results of corporate learning.

Strategy & Growth

We work diligently with you to ensure that your business continues to grow in a healthy way. Rely on us to provide advice and solutions tailored specifically to your business’s needs.

Program & Project Management

This service enables companies to accelerate innovation, bolster organizational effectiveness, and enhance cross-functional team collaboration.

Software Integration & Websites

Problems with systems can disrupt the smooth operation of your company and lead to delays. With our help, you can focus on growing your business.

Virtual Administration

Virtual Administration is a means for businesses to remain competitive and efficient in the digital age. It can provide access to personnel and technology at a fraction of the cost.